Home> Company News> Oil Field Bearing

- Address05 Stanley Street Central Hongkong

- Factory Address05 Stanley Street Central Hongkong

- Worktime9:00-18:00 pm

- Phone(Working Time)+852(3)1591338

Oil Field Bearing Applications:

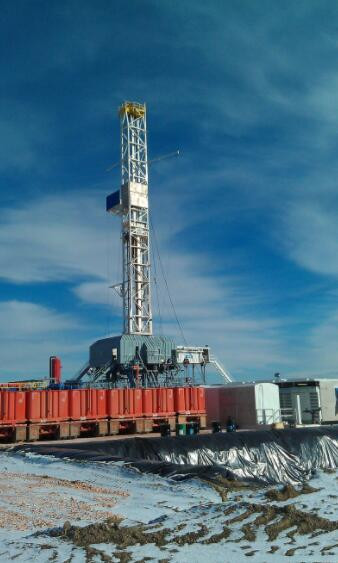

A drilling rig is a machine that creates holes in the earth subsurface.Drilling rigs can be massive structures housing equipment used to drill water wells,oil wells,or natural gas extraction wells,or they can be small enough to be moved manually by one person and such are called augers.Drilling rigs can sample subsurface mineral deposits,test rock,soil and groundwater physical properties,and also can be used to install sub-surface fabrications,such as underground utilities,instrumentation,tunnels or wells.Drilling rigs can be mobile equipment mounted on trucks, tracks or trailers,or more permanent land or marine-based structures (such as oil platforms, commonly called 'offshore oil rigs' even if they don't contain a drilling rig).The term "rig" therefore generally refers to the complex equipment that is used to penetrate the surface of the Earth's crust.

Small to medium-sized drilling rigs are mobile,such as those used in mineral exploration drilling,blast-hole,water wells and environmental investigations.Larger rigs are capable of drilling through thousands of metres of the Earth's crust,using large "mud pumps" to circulate drilling mud (slurry) through the drill bit and up the casing annulus, for cooling and removing the "cuttings" while a well is drilled.Hoists in the rig can lift hundreds of tons of pipe.Other equipment can force acid or sand into reservoirs to facilitate extraction of the oil or natural gas;and in remote locations there can be permanent living accommodation and catering for crews (which may be more than a hundred).Marine rigs may operate thousands of miles distant from the supply base with infrequent crew rotation or cycle.

A mud pump (sometimes referred to as a mud drilling pump or drilling mud pump), is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi (52,000 kPa)) down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling.

A mud pump (sometimes referred to as a mud drilling pump or drilling mud pump), is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi (52,000 kPa)) down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling.

Mud pumps come in a variety of sizes and configurations but for the typical petroleum drilling rig, the triplex (three piston/plunger) mud pump is the pump of choice. Duplex mud pumps (two piston/plungers) have generally been replaced by the triplex pump, but are still common in developing countries. Two later developments are the hex pump with six vertical pistons/plungers, and various quintuplex's with five horizontal piston/plungers. The advantages that these new pumps have over convention triplex pumps is a lower mud noise which assists with better Measurement while drilling (MWD) and Logging while drilling (LWD) decoding.

The construction department should have a special maintenance worker that is responsible for the maintenance and repair of the machine. mud pumps and other mechanical equipment should be inspected and maintained on a scheduled and timely basis to find and address problems ahead of time, in order to avoid unscheduled shutdown. The worker should attend to the size of the sediment particles; when finding large particles, the mud pump wearing parts should frequently be checked for repairing needs or replacement. The wearing parts for mud pumps include pump casing, bearings, impeller, piston, liner, etc. Advanced antiwear measures should be adopted to increase the service life of the wearing parts, which can reduce the investment cost of the project, and improve production efficiency. At the same time, wearing parts and other mud pump parts should be repaired rather than replaced when possible.

An oil platform, offshore platform, or offshore drilling is a mechanical process where a wellbore is drilled below the seabed using a large structure with facilities for well drilling to explore, extract, store, process petroleum and natural gas which lies in rock formations beneath the seabed. In many cases, the platform contains facilities to house the workforce as well.

Oil Field Bearing List:

| Mud Pump Type | Bearing No. |

| 8-P-80 | 24036 CA/C3W33 |

| HM256849/HM256810/C9 | |

| NFP 6/596.9/C9 | |

| NNAL 6/174.625/C9W33YA | |

| 9-P-100 | 24040/C3W33 |

| 3506/333.375/C9 | |

| NFP 6/647.7/P69 | |

| NNAL 6/180.975/P69W33XYA | |

| 10-P-130 | 23144 CA/P63W33 |

| 3506/368.249/P69 | |

| NFP 38/666.75X3/P69 | |

| NNAL 6/187.325/P69W33YA | |

| 12-P-160 | 24052 CA/C3W33 |

| 3506/381/C9 | |

| NFP 6/723.795/C9 | |

| NNAL 6/209.55/C9W33X | |

| 14-P-220 | 23156/P63W33 |

| 3506/409.575/P69 | |

| NUP 6/812.8/P69 | |

| NNAL 6/228.6/P69W33X | |

| F-500 | NU 3228X2/C9 |

| 23138 CA/C3W33 | |

| NUP 464779/C9YA | |

| NNAL 6/101.6/C5W33XYA | |

| F-800 | NU 3036X2/C4 |

| 23148/C3W33 | |

| NUP 464775/C9YA | |

| NNAL 6/177.8/C5W33XYA | |

| F-1000 | NU 3040X3/C4 |

| 24056 CA/C3W33 | |

| NUP 464744/C9 | |

| NNAL 6/177.8/C5W33XYA | |

| F-1300 | NU 3044X3/C4 |

| 24060 CA/C3W33 | |

| NUP 464776/C9YA | |

| NNAL 6/206.375/W33XYA | |

| NU 3044X3/C4 | |

| 23160/C3W33 | |

| NUP 464777/C9YA | |

| F-1600 | NNAL 6/206.375/W33XYA |

| Rotary Table Type | Bearing No. |

| ZP175 | QJF 6/506.43 HC |

| 22322 CA/W33 C3 | |

| ZP205 | 5692/650X1 |

| 5691/600 | |

| 22326 CA/W33 C3 | |

| 22232 C/W33 C3 | |

| ZP275 | 5692/800 |

| 5611/800 | |

| 22330 CA/W33 C3 | |

| NU 2332 EM | |

| ZP375 | 2327/1049 |

| NU 2330 EM | |

| 22330 CA/W33 C3 | |

| Frac Pump Type | Type (Max Brake Power) |

| Triplex Plunger Plump | 600 |

| 1000 | |

| 2000 | |

| 2250 | |

| 2500 | |

| Quintaplex Plunger Pump | 1000 |

| 2500 | |

| 2800 | |

| 4000 | |

| Frac Pump Bearing | Bearing no. |

| 744-742 | |

| K-LM739749-710 | |

| 850-832 | |

| NU 6-292.1 | |

| NUP6-292.1 | |

| NJ 6-203.2 | |

| NJ 6/203.2 M/C9W33 | |

| NFP 6/292.1 M/C9-1W33 | |

| NU 6/292.1 M/C9-1W33 | |

| 306/196.85-2 | |

| 23936 C/P63W33 | |

| NNU 6/25.4-2LSV | |

| NNU 6/19.05-2LSV | |

| 23056 CAK/W33+H3056 | |

| 24036 CA/C3W33 | |

| NF 6/406.362 M/P69W33 | |

| N 6/285.75 M/C9 | |

| N 6/152.4 M/C9 | |

| 306/346.075 | |

| 306/333.375 | |

| N 6/336.55 N2M/C9 | |

| 306/88.9 | |

| NU 3316 M/WB1C9 | |

| N 6/336.55 M/C9 | |

| NUP 3316 M/C9 | |

| N 6/336.55-1 M/C9 | |

| T2AR88.9/190.5 | |

| N 6/406.362 M/P69W33 | |

| NEP 6/393.7 AM/HCC9W33 | |

| 23038 CA/W33 | |

| N 29/530/P53W26 | |

| NF 19/530/P53W26 |

V8A1RX-20S2 V Series Daikin Piston Pump

V8A1RX-20S2 V Series Daikin Piston Pump PV29-2R1D-J02 DENISON, oil pump PV29 series Piston Pump

PV29-2R1D-J02 DENISON, oil pump PV29 series Piston Pump NACHI PVS-2A-35N3-12 Variable Volume Piston Pumps

NACHI PVS-2A-35N3-12 Variable Volume Piston Pumps R918C02383 AZPF-22-022LRR20MB Rexroth Gear pump

R918C02383 AZPF-22-022LRR20MB Rexroth Gear pump R902097362 AA4VG40DA1D8/32R-NUC52FXX5ST-S REXROTH AXIAL-PISTON PUMP

R902097362 AA4VG40DA1D8/32R-NUC52FXX5ST-S REXROTH AXIAL-PISTON PUMP